Hi gentelmen!

I used the hot blade technique and I have to admit it works perfectly!

Thank you for the tip!

I have some update for you of the experiments I did during the week end...

Here is my attempt at the 'swirls' on the cowl:

I used a base coat of titanium silver + 10% flat black, a wash of china black ink (a 20% water dilution) and then I used a silver pencil, here is the pic of it

What do you think? I fear I have to practice more...

Next a pic of the left cockpit frame

and the engine...

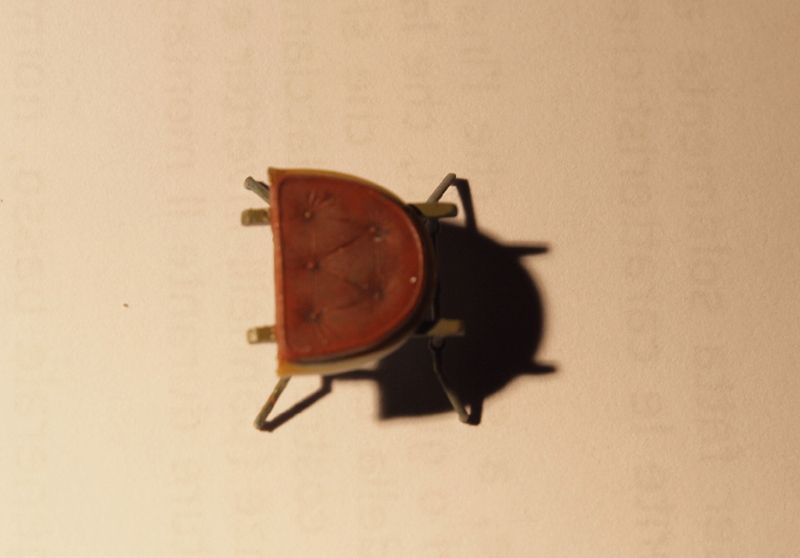

... and the seat.

I was disappointed by the dash board. Its detail are very soft and my expectation were much more higher (so even WNW does not everything perfect, and this should be a great stimoulus for any competitor willing to challenge them on the market...Roden do you hear?)

so I decided to scratch build a new one, well I am very proud of the result: what do you think? (on the right habd side is the pulsameter).