Evening All,

Thanks to all of you who have dropped in and left such positive remarks. I particularly appreciated them this time following the earlier mini-fiasco!

The first piece to be made after I had assembled the fuselage and nose was the cockpit glazing. I made this in a single piece of clear 20 thou acetate sheet which was plunge moulded in the usual way. I needed to add a little filler at the top to get the contours right but this will not matter as this area was covered on the machine - the glazed parts were lower down. It is noteworthy too that the pilots did not have a windscreen - there was a large hole with side windows and windows above the hole. Later after the wings were fitted I added framing from 10 x 20 thou Evergreen strip.

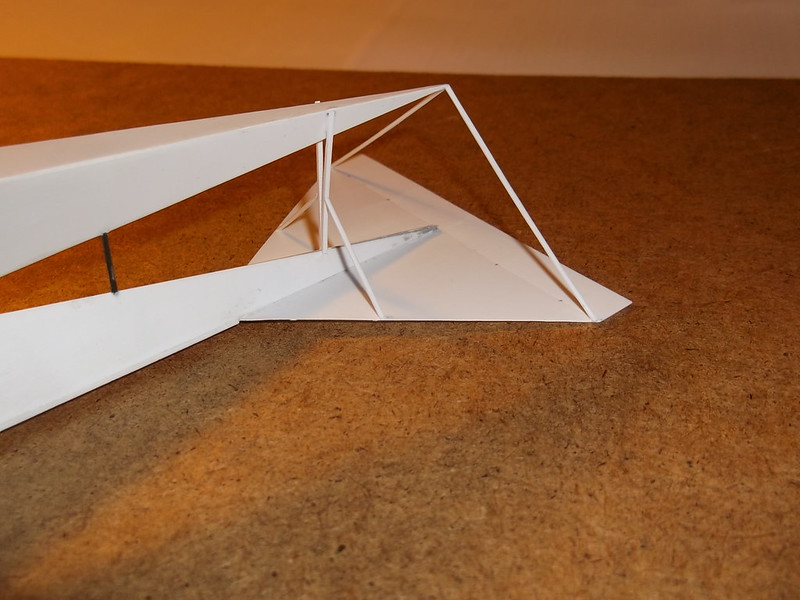

I fitted the lower wings one at a time. The pins which I had put through the bottom of the fuselage were to go into holes which I had drilled into the ends of the wings. I had to tidy the ends of the wings a little with some thin card because the laminations had left some uneven edges. When I had dry fitted the wings and checked that all was aligned I started with the starboard (right) wing. Superglue was put on the ends of the pins and cement to the plastic edges of the wing. The wing was then attached to the pins and supported while the cement dried. The superglue dried quickly and held things in place but I decided to take no chances and left everything for an hour.

The struts had been pre-cut and shaped from 30 x 60 thou Evergreen strip but they had to be trimmed to fit exactly. I measured the gap with dividers and final trimming was done by offering the strut to the hole. The inner rear strut was placed first and allowed to dry for 10 minutes.

The remaining struts could then be fixed and the lower wing was firmly in place.

The above procedure was repeated on the port (left) side. Finally the upper wing overhang bracing struts were fixed into place.

Now the horizontal tail surface could be fixed to the top of the rear fuselage and the struts glued into place. These were made from 20 x 30 thou Evergreen strip.

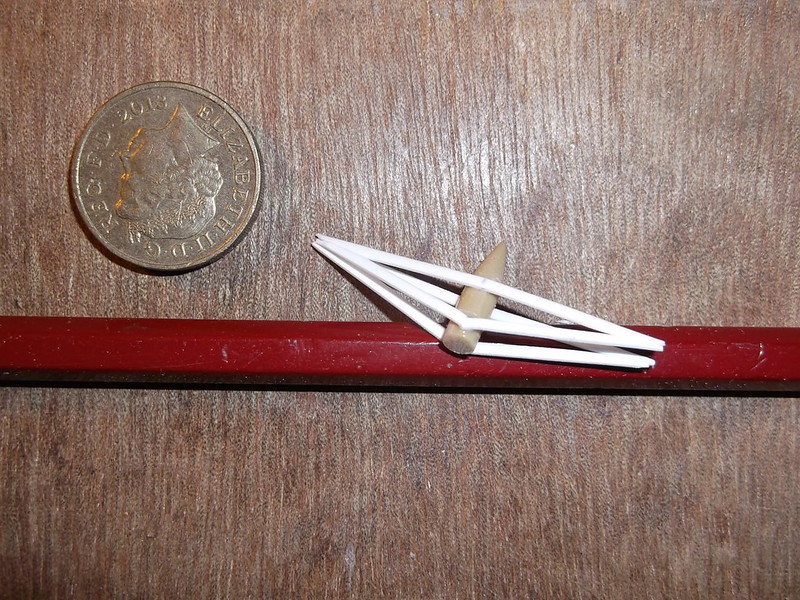

I assembled the gearbox bearer struts. These too were Evergreen strip (30 x 40) which was sanded to aerofoil section. I measured the rear struts first and then bent them gently at the mid point before gluing them to the sides of the gearbox. The front struts were shaped and then cut in the centre and the corners at the rear of the centres cut off so that when the struts were joined to the gearbox the tops and bottoms met the rear struts. This sounds complicated but I hope the photos show what I mean. I did not glue the top and bottom of the strut assemblies until all four struts had set on the gearbox. Finally after the struts had been glued together both sub-assemblies could be inserted between the wings and glued into place.

The next stage will be to paint the model: this will take time as once again I am about to go on my travels.

Thanks for looking.

Stephen.