I looked at the build sequence as if i was building a real aeroplane, the fuselage frame is the place to start, everything else gets nailed to it.

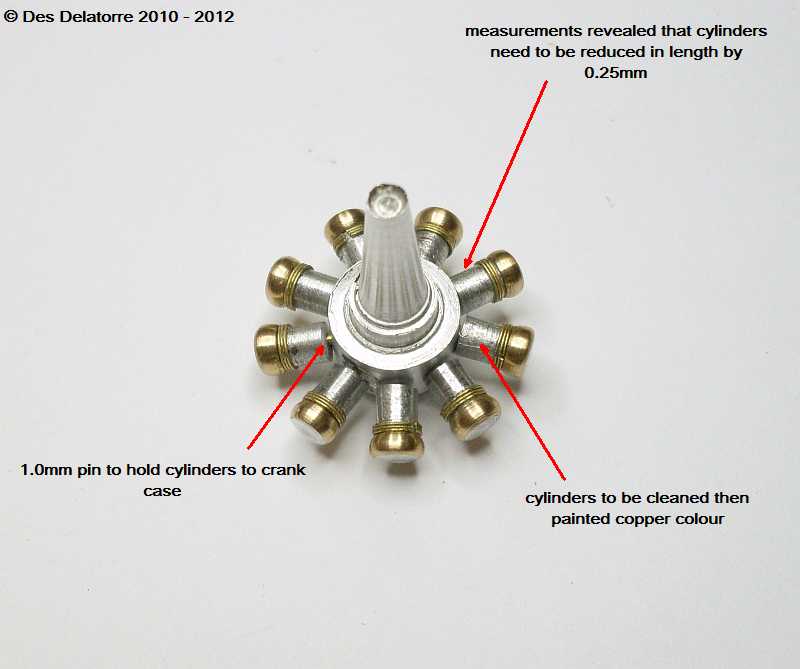

The cylinders are made from 4.0mm aliminium rod, a brass tube was placed on top then shaped to suit the photos I have of this engine. I made a grid on my computer drawing program to get the nine equal spacings for the holes in the crank case for the cylinder placement, a hole was drilled in the bottom of each cylinder and a pin will hold them to the crank case.

This picture shows the nine cylinders sitting loose on the crank case, it was important to get the spacing exactly correct. I will use CA to hold the cylinders in place, along with the pin they should be quite strong. Not having any dimensions it is a trial and error thing, fitment in the fuselage frame revealed the cylinders to be too long, adjustments need to be made.