Before I got too far along I decided to do a plan for the rigging, and to try out an idea for the bound lines around the engine area.

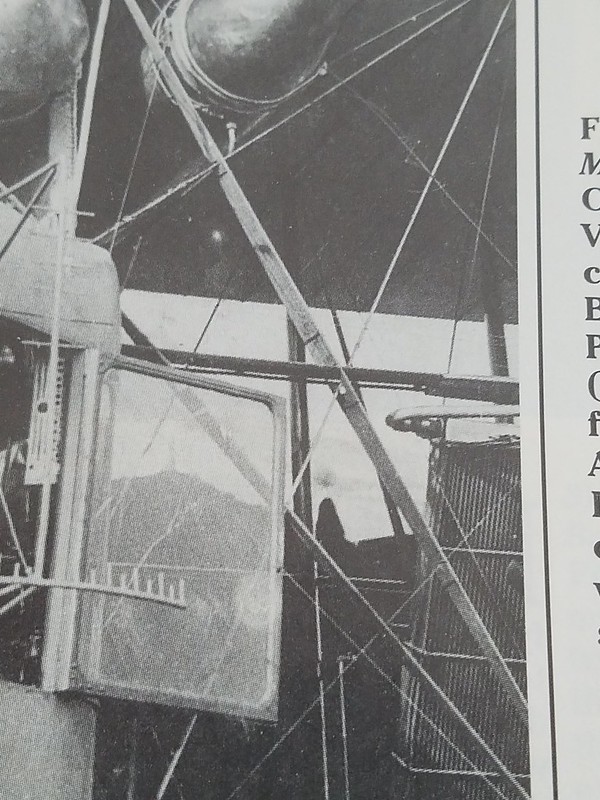

To explain a little: The rigging wires in the area of the the props were double or triple wires, with a wooden strip added between them. The whole was then bound to form a solid piece which would not result in loose cables fouling the props should they break.

This photo shows what I mean. It is used with the kind permission of Ray Rimmell/Albatros Productions.

You will also notice that the wires in one direction go around (or through, depending on which one you're looking at!) other wires - another complication!

Originally I'd thought of simply using thin strips of plastic rod or sheet, but I couldn't think how to get the look right where the wires passed through each other. That led me to thinking in a different direction, but I needed to try it on a dummy run to see if it would actually work. That brings us to the trial...

I put together a couple of pieces of scrap to form a small jig, then attached some "rigging wires". The idea was to use either white glue or Mr Surfacer to fill the gap between the wires. I started with Mr Surfacer, mainly because it's grey so it wouldn't need to be painted afterwards! I have both the 500 and 1000, and decided to go with the heavier 1000. Immediately I could see that it could work, so instead of white glue on the other side of the jig I used the 500.

This is with just one large "blob" added to one end and drawn out with a small brush. The 1000 is certainly easier to apply as the 500 wanted to pull along the wires and I had to drag the ends back down with the brush a couple of times. The key seems to be making sure you have a good sized blob (technical term!) on the brush to start with.

Here's one showing both sides, with a ruler to show the sort of gaps I'm dealing with. There's a slight dip in places but nothing that a second coat shouldn't sort out, and more importantly, it hasn't sagged underneath but has stayed taut between the lines as required, It is also flexible and doesn't crack if I press on the wires.

This should also enable the wires to be run around each other with no problem. I think that problem has now been solved, so more rigging holes are needed before moving on.

Ian