Dear friends,

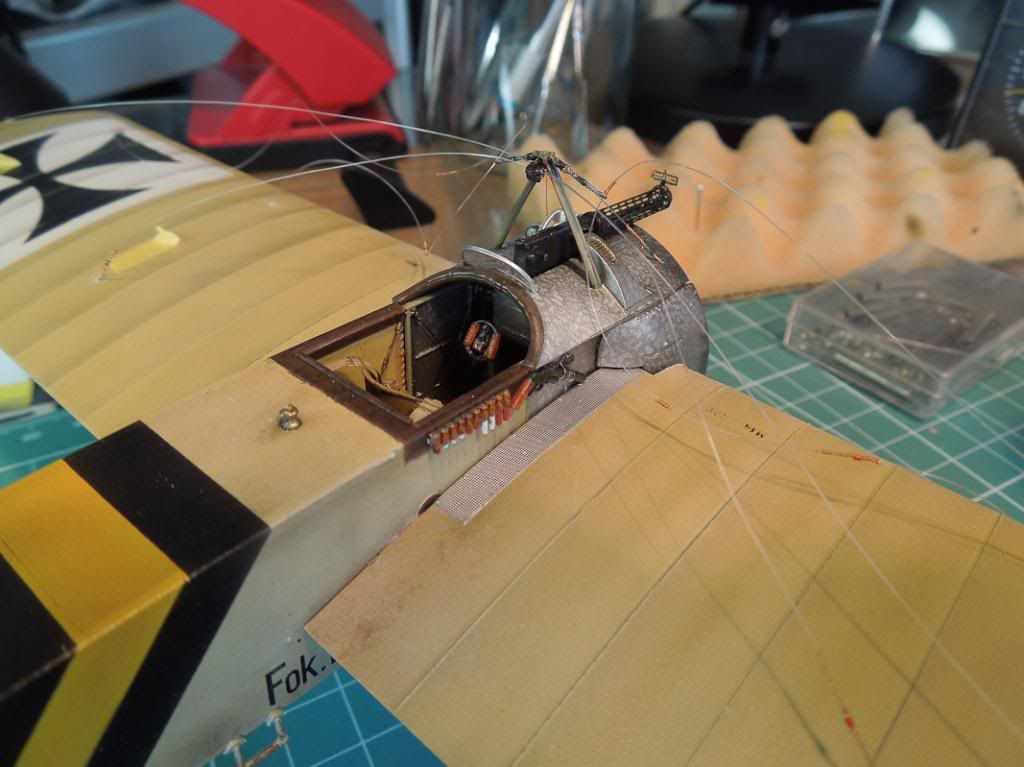

here are some pics of the rigging of the top side. The overall structural rigging was done by using 0.12 Fluorcarbon monofilament. I chose structural rigging instead of EZ-Line because of my suspicion that the wings will tend to bend downwards due to time and force of grafity.

Planing the steps of rigging was essential because after the top side rigging, the plane can't be laid on its back anymore. The rigging of the under side of the wings was done in back position with some tension on the monofilament.

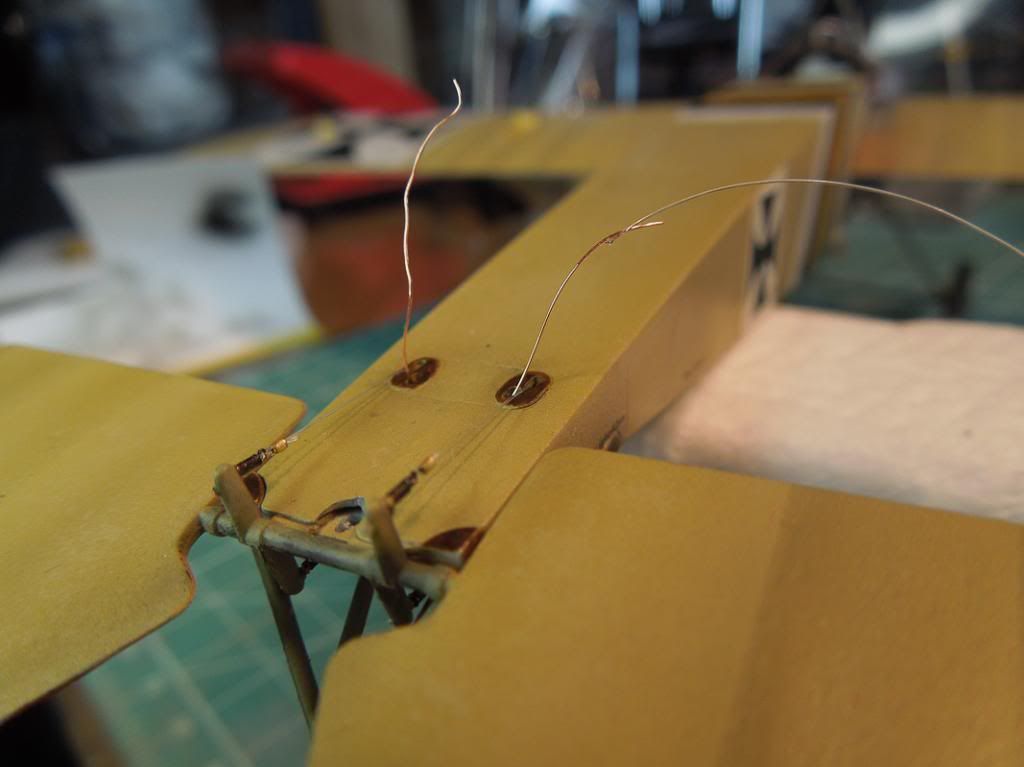

First I added the control cables for the rudder and the elevators by fiddling a piece of bended copper wire through the whole and fixing the monofilament on the end of the wire with Cyanacrylat.

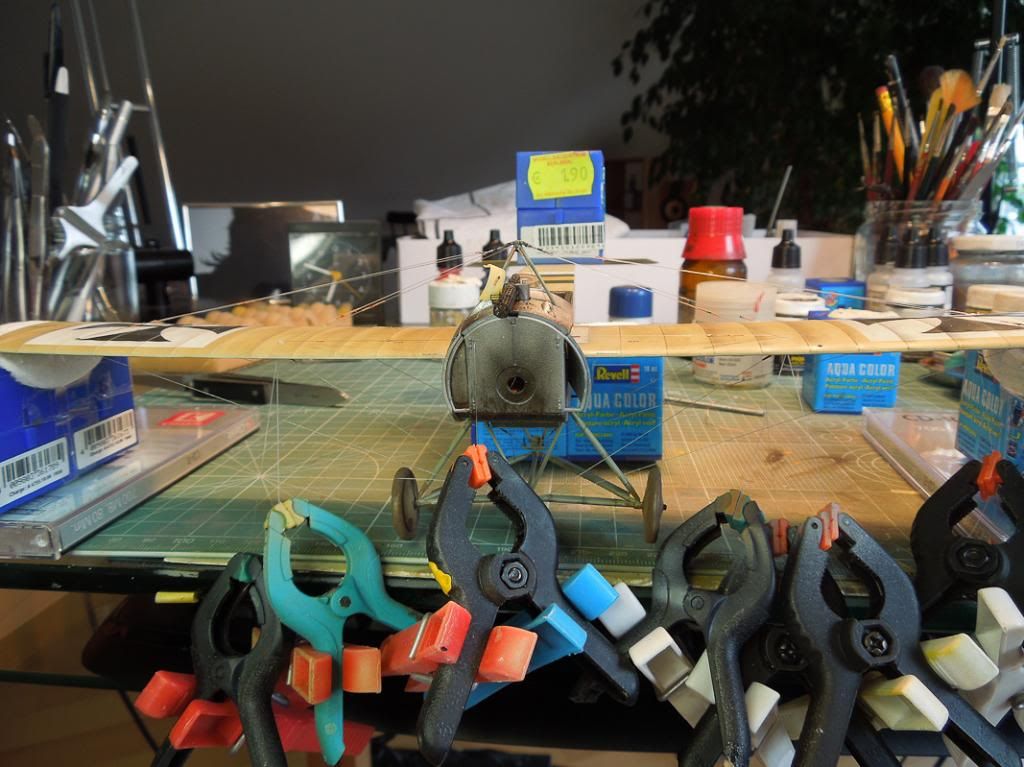

After the plane was turned on its carriage, the monofilament plunged down a little bit due to the weight of the wings.

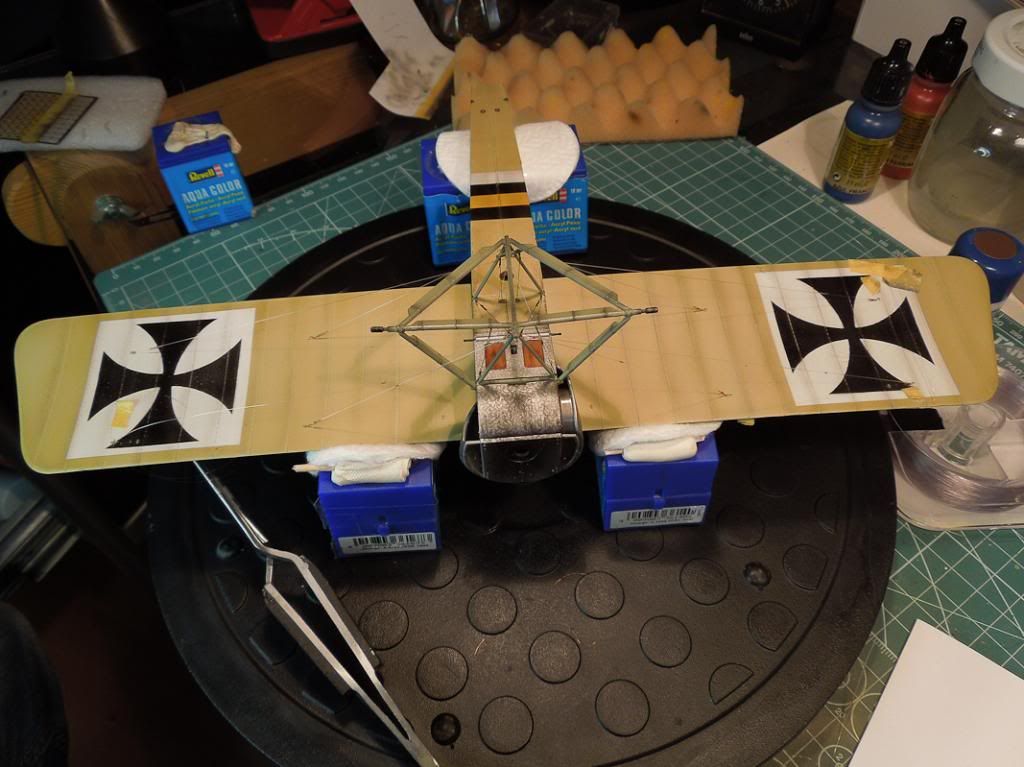

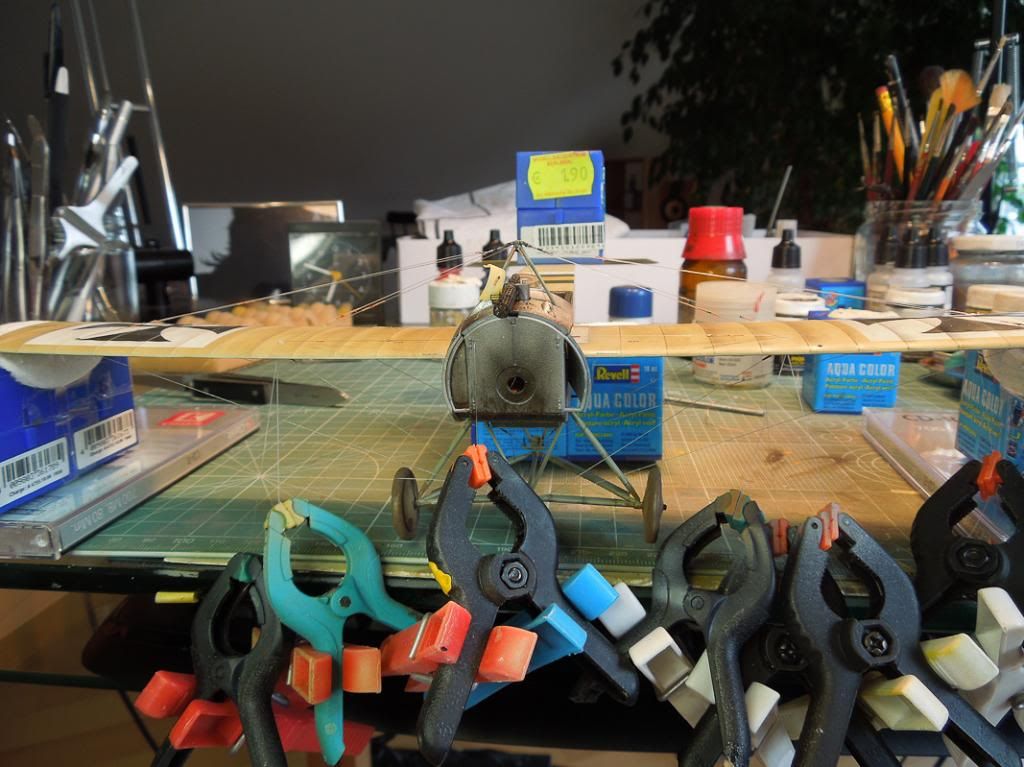

For the rigging of the upper side, the tips of the wings were placed on revells acrylic pots. This caused to bend the wings towards the upper direction and let the bottom monofilament gets its tension back. The upper rigging was prefixed and clamps, weigthened with extra clothespins kept the monofilament tight.

All upper monofilaments were fixed with Cyanacrylat in one step of procedure. After letting the Fokker back on its carriage again, the tension was evenly spread throughout the under and upper side of the wing.

Happy to share this with you after this delicate step is done...

Cheers, Dirk