Evening All

Thank you Richie, Alexis, William, Mark, Rick, Ken and Frank for your support and generous comments - they are very helpful indeed.

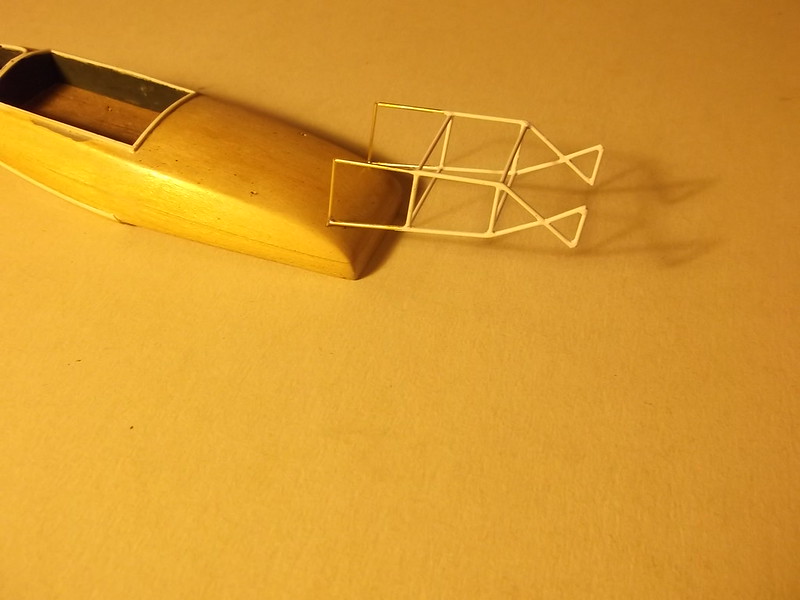

As Frank in particular and the rest liked the soldering in my last post, I decided that I would do some more. The propellors on this aircraft were supported on two booms and were connected to the engines by drive shafts. The booms were braced by a rather elaborate construction which was placed over the engines: the whole is a rather intricate structure with lots of small pieces. I thought that I might try to make the whole assembly from brass rod until I looked carefully at some of the joints - and then changed my mind. I will make the propellor supports and the rear of the cage from brass rod to give the structure strength, but much of the bracing over the engines I will fill in with plastic rod as I will have to assemble it in situ and soldering that would be impractical. If you are a bit bemused, all will become clear at a later stage of construction. So for now I have made the propellor supports from brass rod as per the tail boom:

These have since been primed with the tail unit parts shown in the last post.

The wings caused me some problems. There are 4 of them and I originally cut them form 30 thou card which had been bent in boiling water in a piece of drain pipe. The lower rear wing is in 3 sections as the outer panels are very slightly swept back. Similarly the upper wings are in two parts because the leading edge is not straight. The lower front wings were simply cut from card. All sections were sanded to give a slight aerofoil shape and ribs glued in place: these were 10 x 20 thou Evergreen strip applied with liquid cement. The strips were sanded and then 500 grade Mr Surfacer filler was applied to the edges and the whole sanded again. The rear wings were fine, but when tested the front lower pair had too much curve and would not sit firmly on the top of the hull and give sufficient contact to ensure that when glued in place they would stay there. I also looked at the photos of the aircraft and saw that the aerofoil on the front pair of wings, especially the upper one, was almost nil. So I cut a second set of front wings from 30 thou card, applied the ribs and filler, sanded them twice and tried again. This time I found that the lower wings just did not have enough strength to be sure that they would not sag at the tips when the upper wing and struts were placed on them. So I made a third pair..... from laminated 20 thou card which had not been bent in hot water. This time I managed to get wings which may not be 100% accurate in terms of aerofiol section, but they will have the strength and surface area to stay in place and not bend (I hope!)

The upper pair are the front wings and the lower pair are the rear wings.

I have lined the interior of the engine compartment and front cockpit with 10 thou card but as I have no idea about what the interior was like I am using modellers license and following Marklo's suggestion that there was a floor made of wood to help support the engines at the correct level. I made up a floor from pieces of stripwood laminate. I also made up the platform for the trailer which the aircraft was carried on at the same time. This was also stripwood and the beams obechi. Both the floor and platform were stained with a wash of Revell brown 381 acrylic:

I checked that the tail boom will fit properly into the rear of the hull. This was useful as I was able to use the structure to make sure that when I cut the horizontal tail surface it will exactly fit:

I have started to make the engines but have only laminated plastic for the blocks and cut rod for the cylinders - construction, detailing and painting will be shown next time.

Thanks for looking.

Stephen.