Okay folks, here we go! I have enlarged my drawings to 1/32 and made templates for the parts to be cut from sheet styrene, i.e., the wings and tail planes. The fuselage will be made by constructing a frame of 1mm (0.40) styrene strip to be covered with .25mm (0.10) styrene sheet. The cowling will probably need to be vacuformed or push molded because it has vent holes than will have to be cut from the plastic. A solid or built-up shape simply won't work.

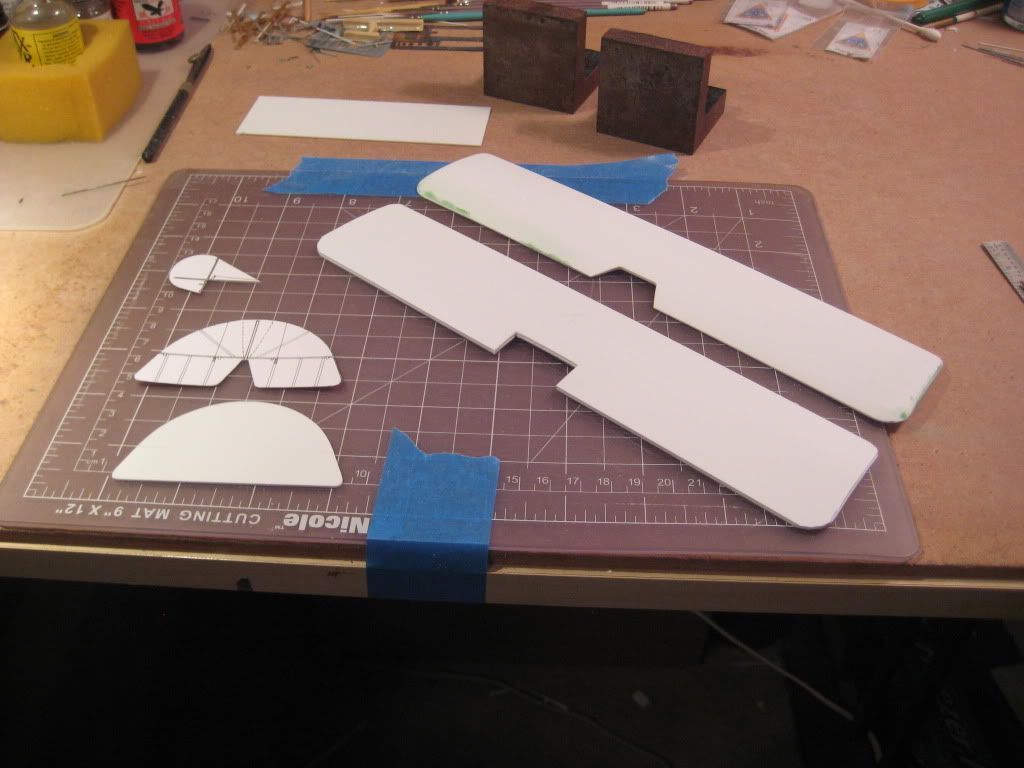

I decided to start with the wings, and followed Des's technique of cutting out two 1mm sheet styrene "blanks" in the plan shape of the wings and gluing them together with Humbrol liquid cement and then clamping the wing into the airfoil jig overnight. See Des's Caudron and Bleriot build logs on the main site for a full description. Here are the parts cut out and glued together after an evening in the jig, with the top wing partly sanded and the bottom wing out of the jig but unsanded:

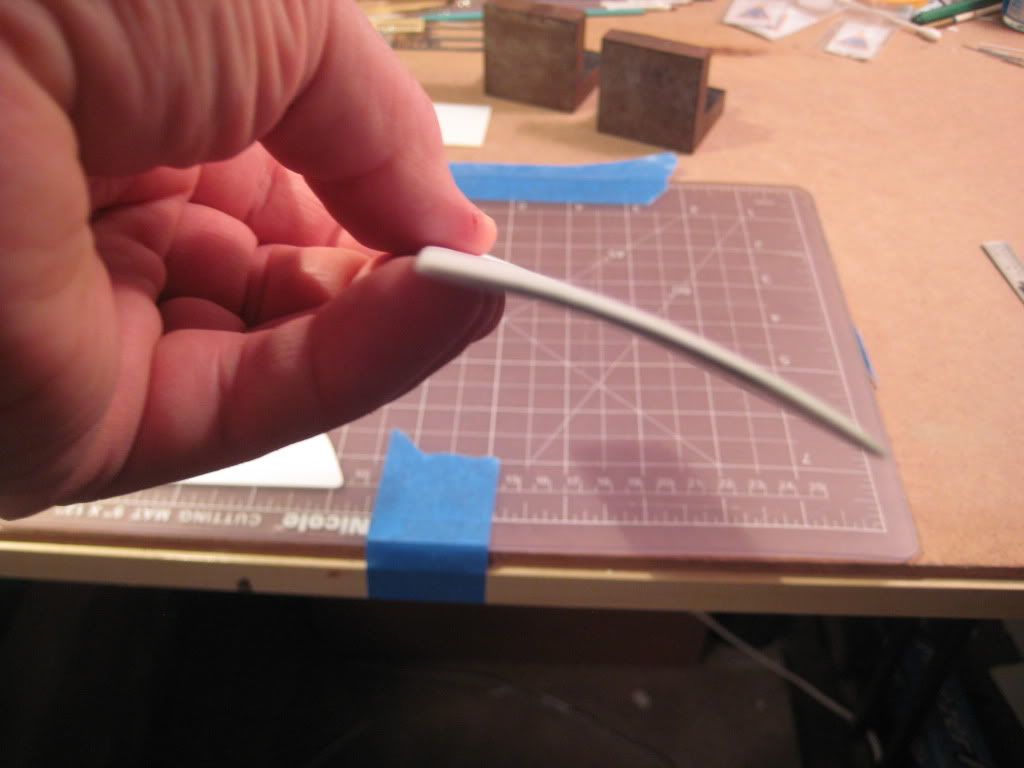

I will discuss details of the bottom wing when I begin working on it. Once sanded to the correct taper, I will use Von Buckles strippers for rib tapes and spray with auto primer, again per Des. Here is the sanding progress on the top wing, in cross section:

As Des has noted, this wing technique involves a lot of sanding. I'll come up for air in a few days and let you see how they turned out. Strippers are in the mail, and will arrive in about a week or so. More later.

Regards,

Bob