Hi all,

I was thinking about modern day kit production methods.

First off I don't want to be too contentious on this subject.

One off the major costs of producing a model kit in styrene is the cost and time involved in creating the injection/slide moulds.

The retail cost of kits depended largely on this, so it was no surprise that the more finely detailed and complex kits cost more.

I think even the initial cost of some of the early 'Wingnut Wings' kits was higher than expected due to this.

Then we have resin kits, which traditionally cost more than styrene kits due to the manufacturing methods used.

The techniques of creating the moulds differed to that for styrene moulds and I assume the cost of resin was higher.

However we are now seeing more 3D printed parts being created, either by individuals or by manufacturers, such as 'LukGraph'.

This brings me to my thinking.

The initial cost of setting up suitable 3D printing equipment is probably high, but not as much as the cost of creating injection/slide moulding tooling.

The larger and less complex model parts are moulded and it's the intricate, smaller and more complex parts (a major cost in injection tooling) that are 3D printed.

Once the kit parts have been created in CAD etc and test prints carried out, production of identical parts can be started at the cost of materials only.

Also, 3D CAD designs are quicker and easier to modify to create other versions of those model parts.

There is no doubt in my mind that kits from 'LukGraph' and 'CSM' have filled the gap left by the demise of 'Wingnut Wings', both in quality, presentation and subject matter.

However, I assume that for most modelers, much of the satisfaction in modeling is in the challenge of building assemblies, such as the engines, rather than just adding 3D assemblies.

Even though the cost of living generally keeps increasing, I can't help wondering why part moulded and part 3D printed kits cost as much as they do?

My thoughts are that the more a kit is 3D printed, the less production costs are involved and therefore in theory, the retail prices should be lower than they are.

As I said I don'y want to be contentious - just the thoughts of one modeler among many

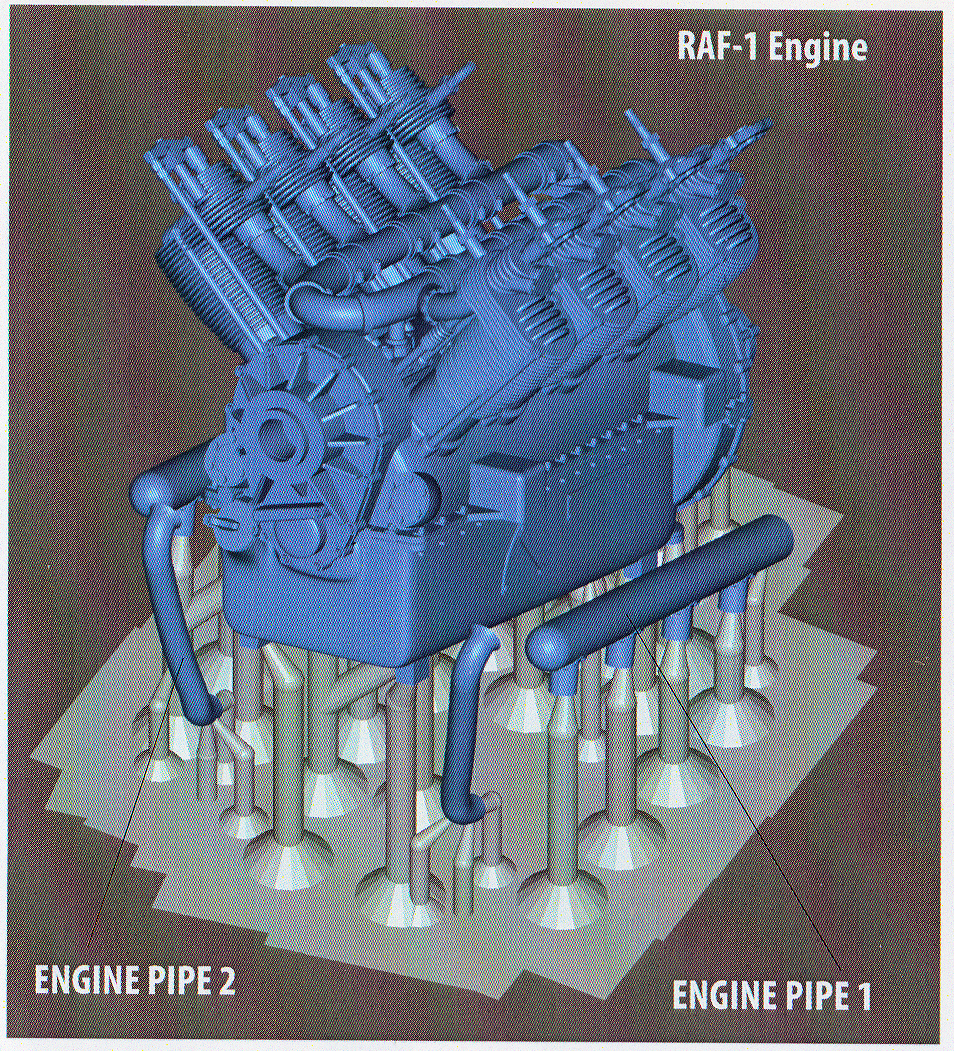

Anyway, first up will be the engine.

As you can see the complete engine is 3D printed, with probably only ignition leads to add.

So in theory just separating the five parts from their supports, removing any residual support tags and sanding away any obvious layer striations.

We'll see

Mike