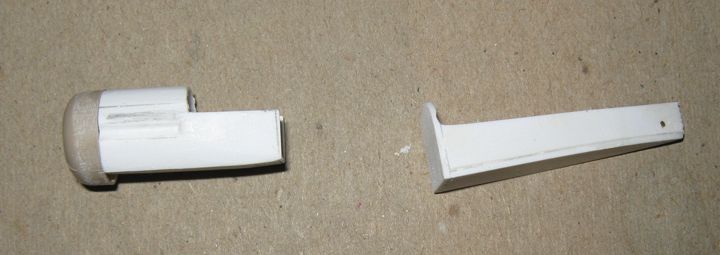

The nose requires a good deal of taper down from its round front. It began as a 'box' with 3mm sheet at top and sides, and 2mm sheet at bottom, with a disk matching the cowling piece in front. This was sanded down to shape on the outside, and then rounded out on the inside (with heavy grit on dowel), as much of the area under the top decking is part of the cockpit. The rear portion is a pretty straightforward box, though there are some complexities to the shape of the turtle-back that will be added. The cowling piece is simply tacked on, there will be considerabl

This picture came out a bit fuzzy, but it shows what is left of the thick sheets employed, taken down to about half to three-quarter millimeter thickness. The recess for the barrel of the Vickers is a piece of 2mm tube, sanded to half-round, installed in a slit cut into the side after shaping, and then opened up a bit further.

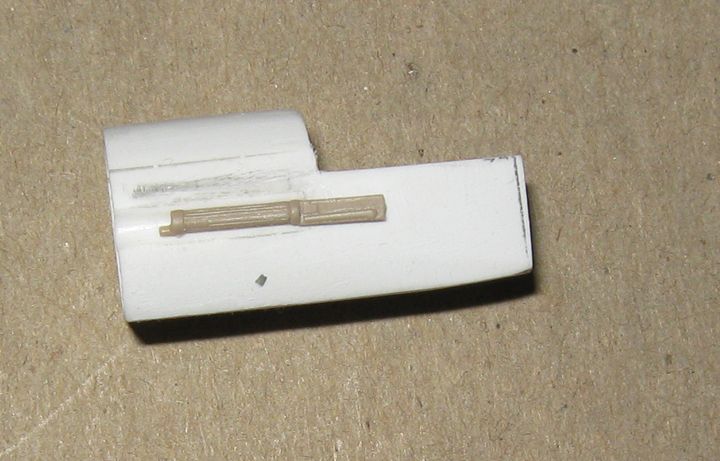

Here is an Eduard kit Vickers fitted into the recess (purely for demonstration, it will not be the piece used).

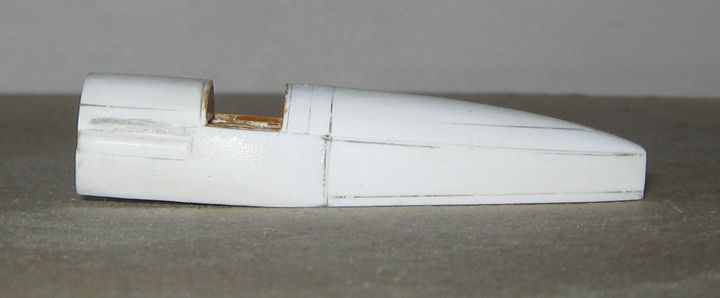

Now the nose and tail fuselage sections are joined, and the turtle-back put on; all that remains for the basic fuselage is the decking around the cockpit opening.

The turtle-back over the straight-sided portion of the fuselage is a laminate of 2mm and 3mm sheet, trimmed to plane and sanded to profile and section. The portion immediately behind the cockpit is made of three vertical pieces, two of 2mm and one of 1mm sheet, and a 1mm piece was added in front.

Sidewall structures were added from the top or through the still open nose, after the fuselage portions were joined and the basic turtle-back was on. Final interior elements will be inserted by the same avenues.