Hi all - for quite some time, I've wanted to do a 'skeletal' scratch build, i.e. build an aircraft with the 'fabric off', so to speak, in my favourite scale of 1/48. I've recently ventured my first steps into this scratch build subject - a scratch built 1/48 Morane Saulnier Type L parasol. I selected this aircraft as my first attempt as it was a relatively simple aircraft, and would allow me to practice some techniques before I tackled something more complex.

What has stopped me to date has been the ability to consistently produce wing ribs - I've tried a few methods in the deep dark past, but nothing really worked. For the last year or so, I've been using a small plotter / cutter to cut painting masks, and a week or so ago I decided to see if I could cut thin (0.010") plastic with it. After fiddling with a few settings, I worked out that I could cut the plastic sufficiently to make such a project at least a little viable. So armed with the Windsock Datafile, I went to work.

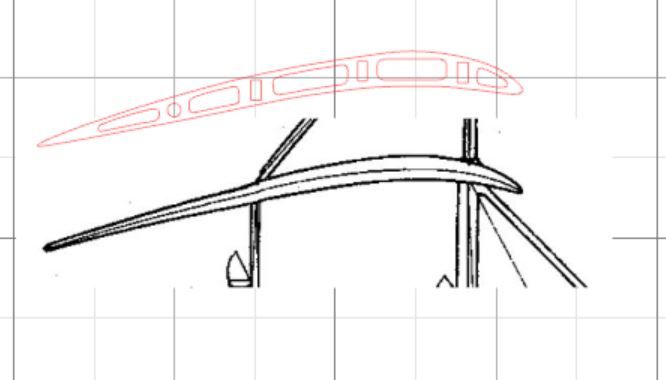

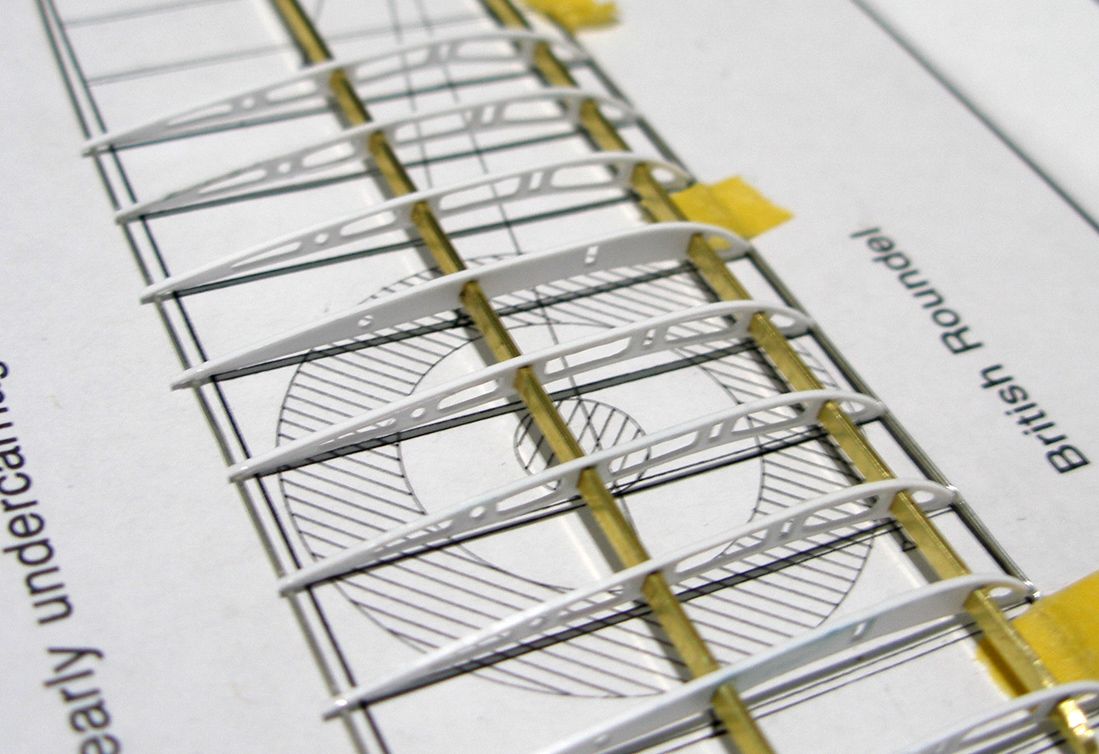

The first step was to draw up the wing rib profile. I had no data on the wing construction, other than the profile in the data file, and a few pictures which suggested some of the structure. So I made up something that at least looked plausible. The profile had to be a little thicker than in reality, to account for the brass strip that I had available to use as spars, but the approximation was good enough. Here was step 1:

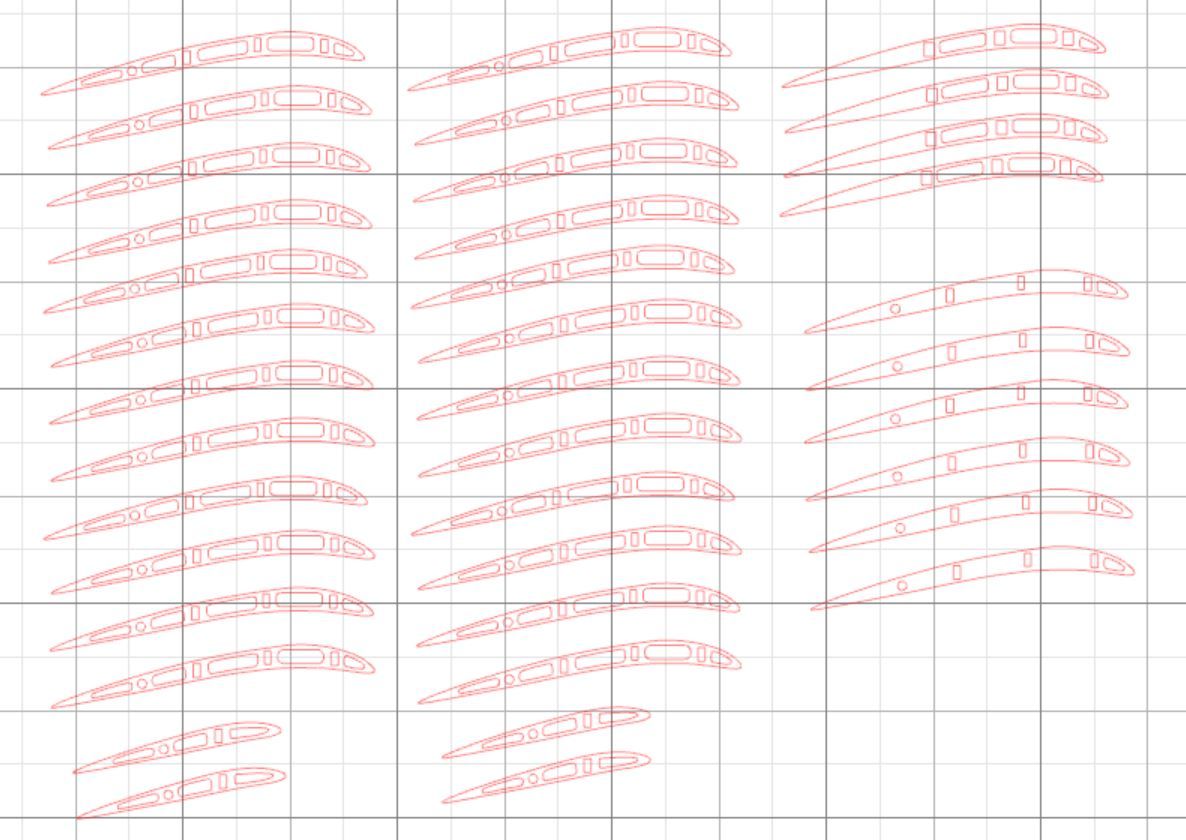

Next came lots of copying and pasting, and some more adjustments, to come up with the full 'suite' of ribs. Again, I had to make some guesses as to the structure.

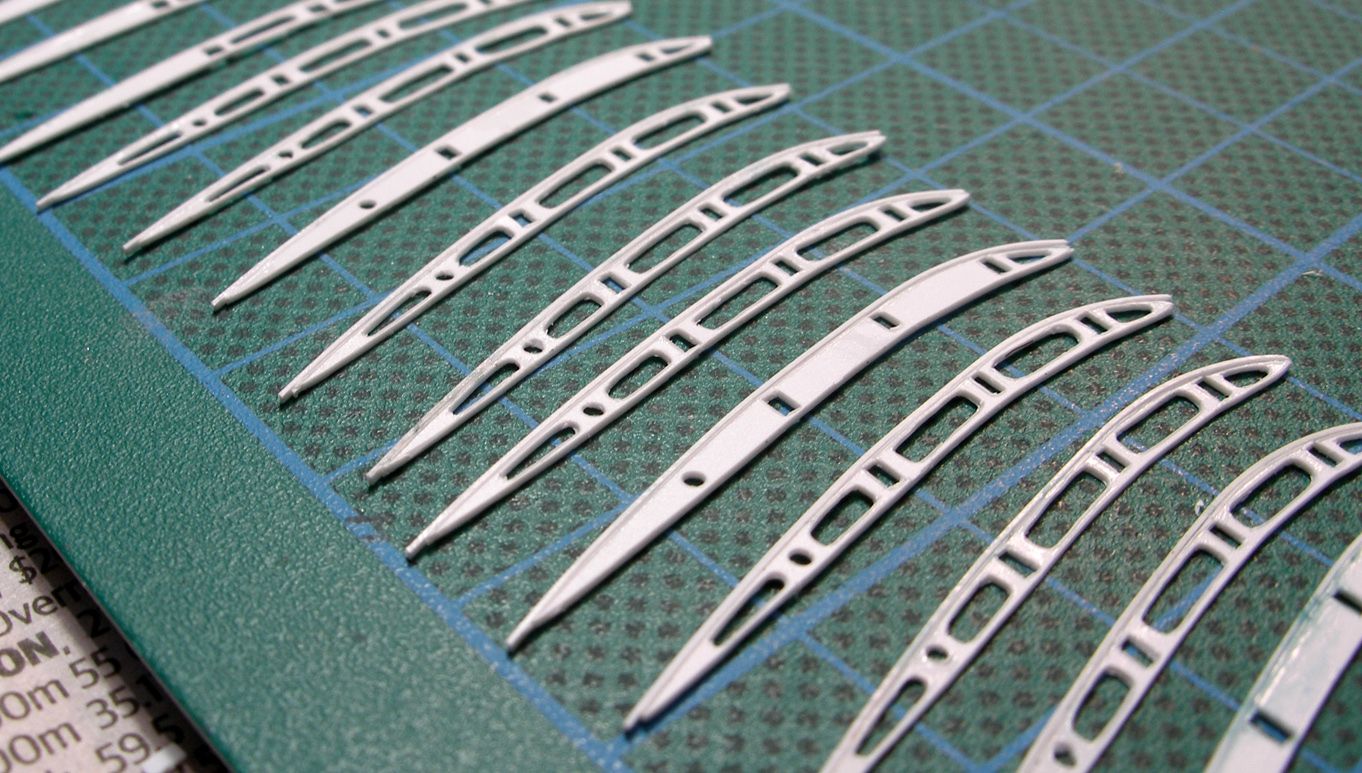

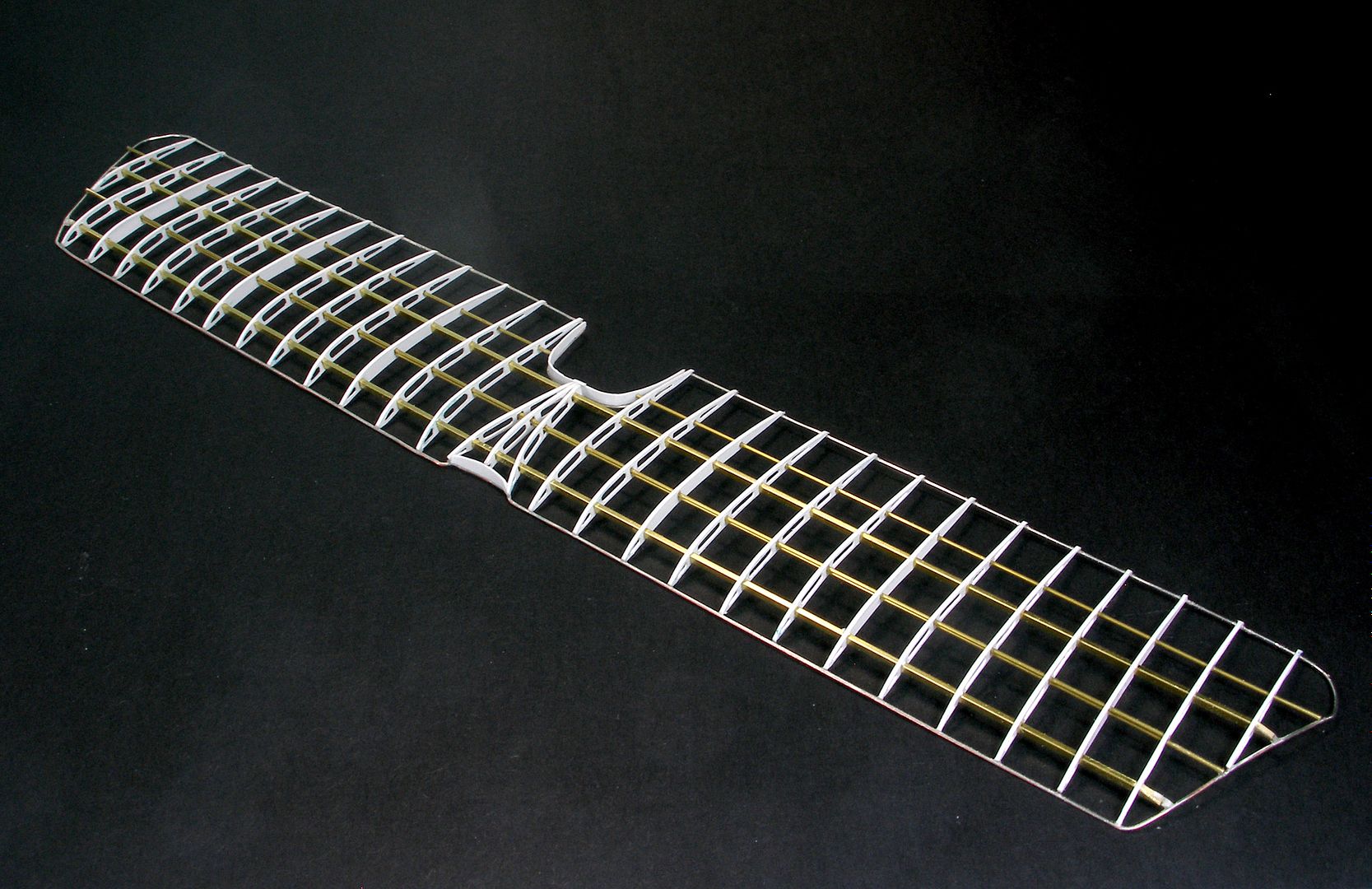

After 45 minutes or so of cutting the 0.010" plastic, my plotter produced this:

As the plotter couldn't quite cut through the full depth of plastic, lots of prying, scoring, and general mucking about produced the wing rib profiles I needed. Unfortunately, being so thin, the ribs were very bendy. I thus added spar caps using 0.010" x 0.030" strips; these helped to 'straighten' the ribs:

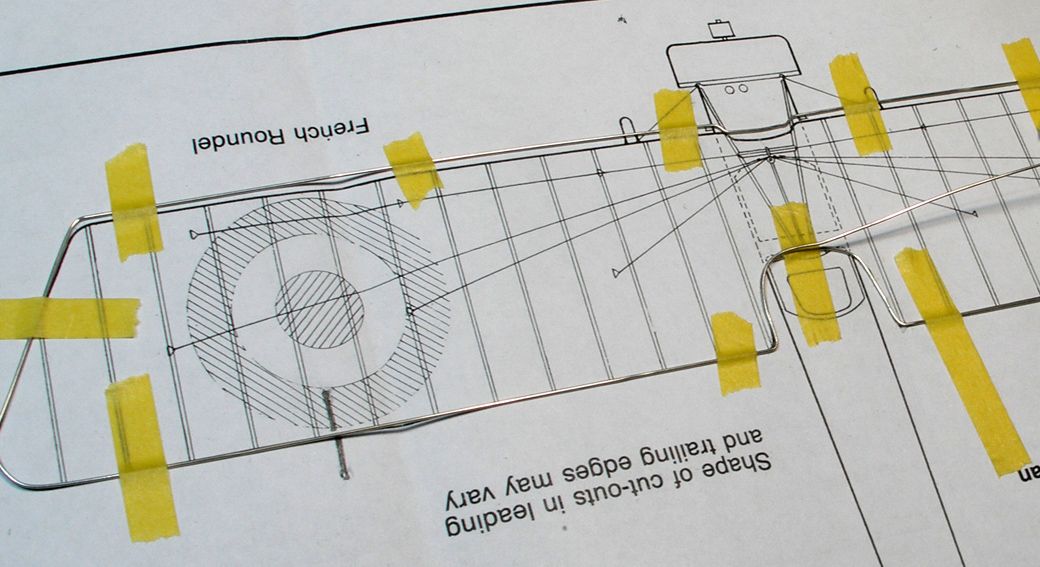

Next I bent up some wire to replicate the leading and trailing edge wires using the datafile as a guide, leaving a little extra as the wing 'droops' so much in profile:

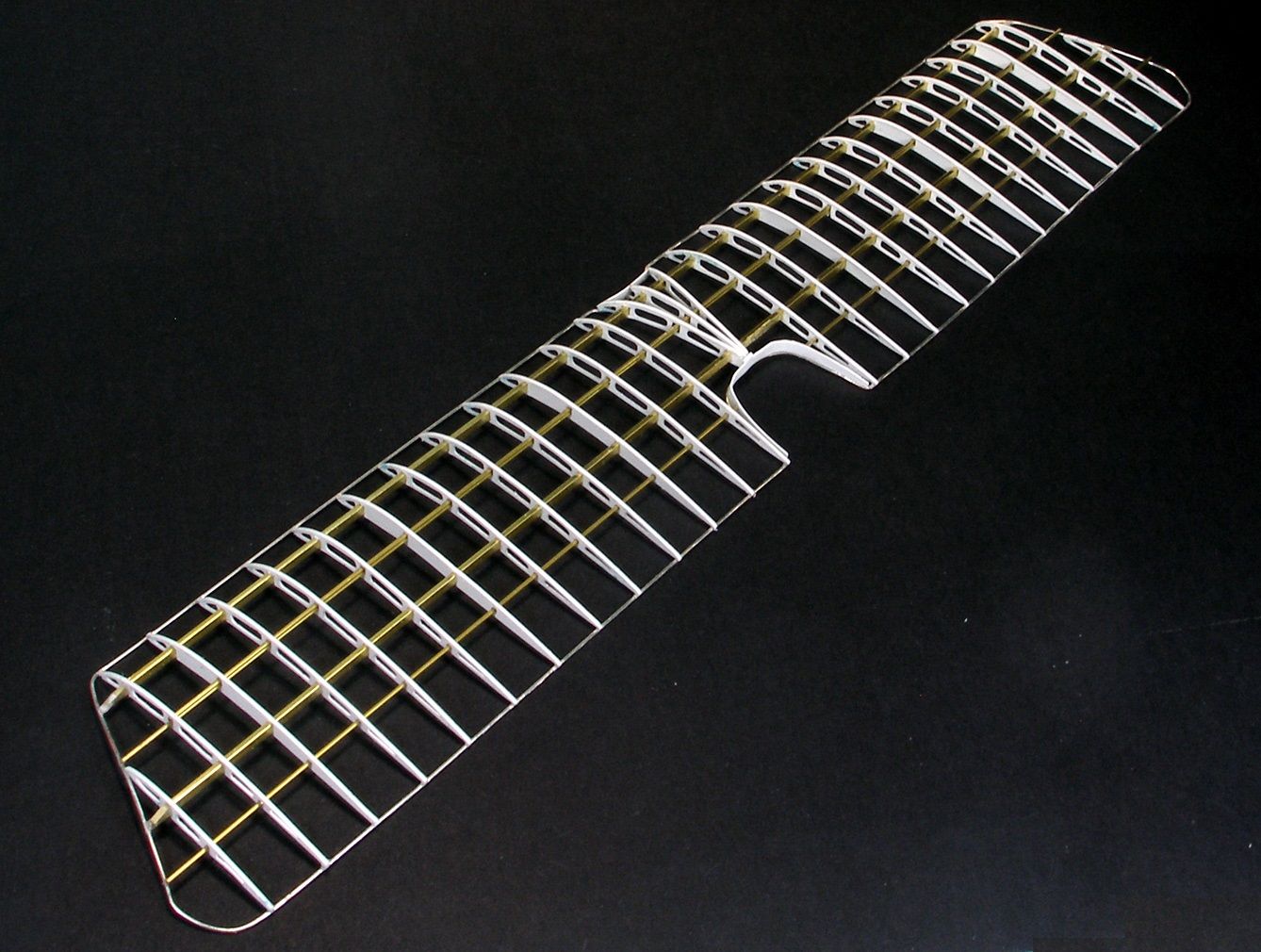

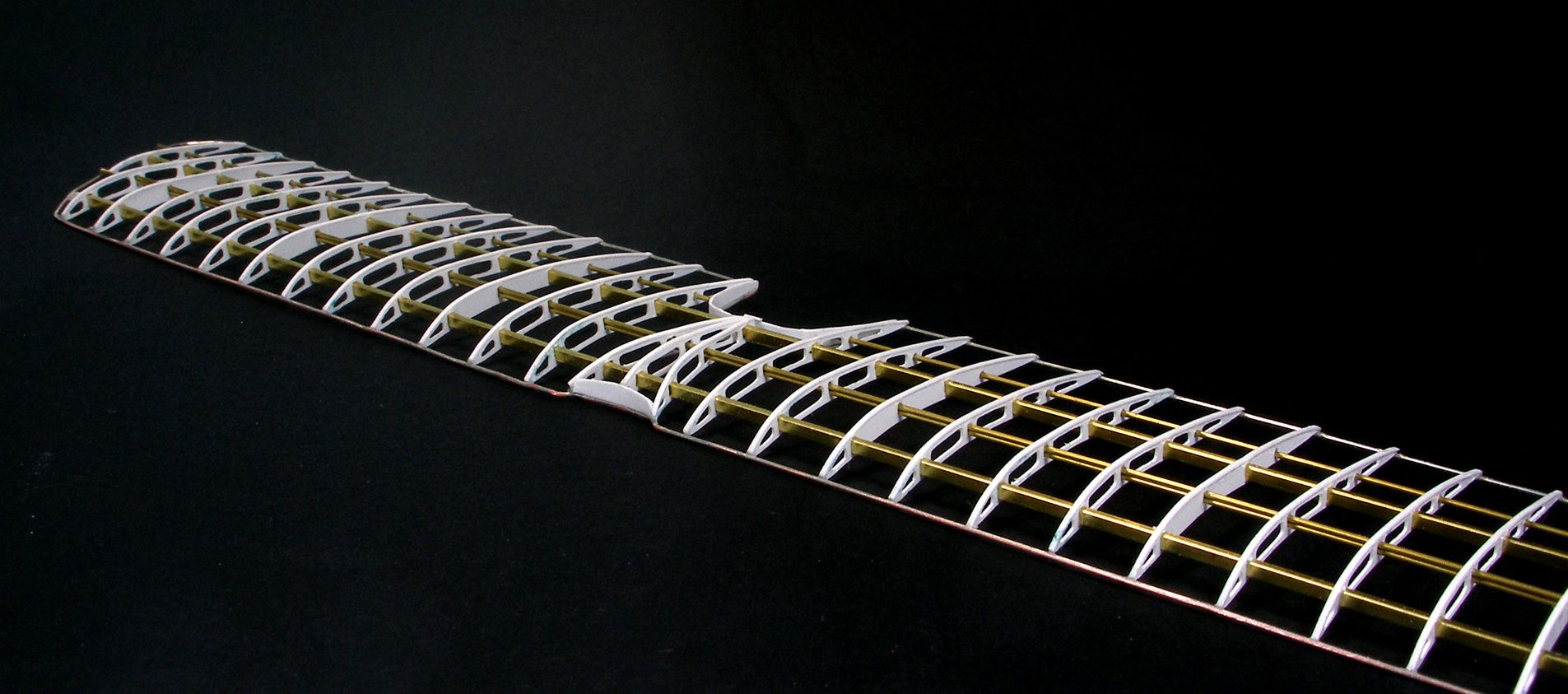

I then added spars from brass strip for long term rigidity, and started to 'thread' the ribs over the spars and securing them at the spacing as per the datafile:

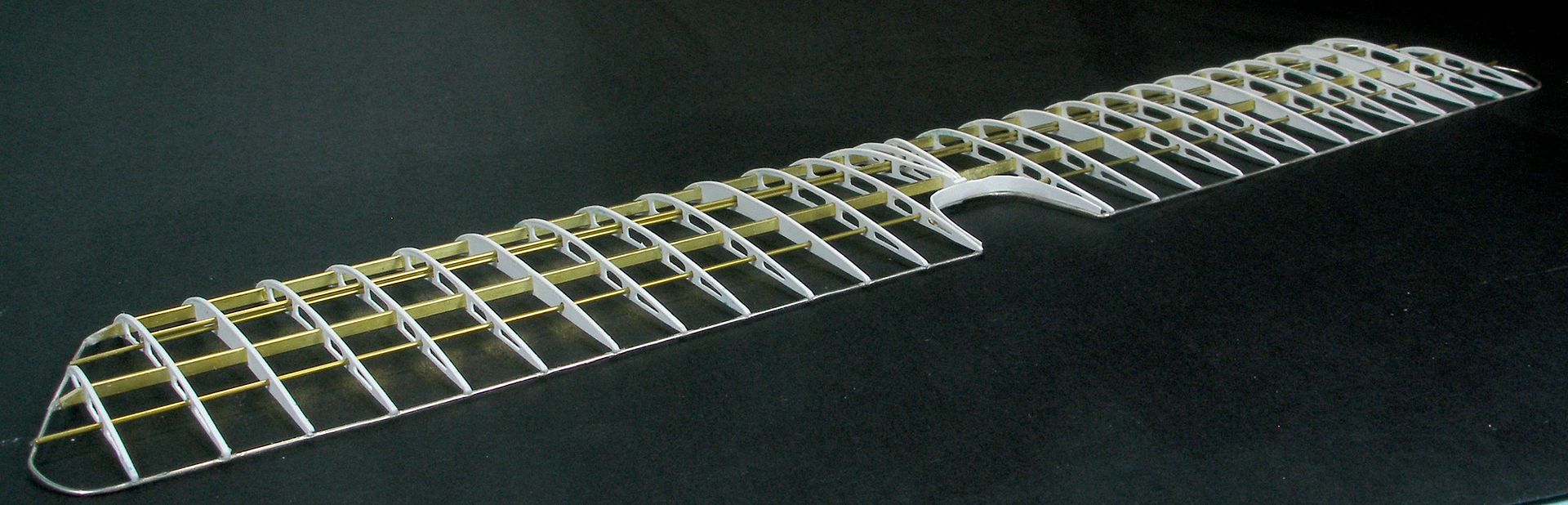

Sub-spars were then added, and here is where the wing currently is at:

There's still some clean up to do, and more details to add, but the basic structure is now there. It is surprisingly sturdy (and lightweight). I'm reasonably happy with this as my first attempt. Now that i've done this, no doubt someone will post plenty of pictures to tell me how wrong I got it, but oh well...!

Next will be tackling the major fuselage frames - I just need to get hold of the right kind of brass strip, at which point, i'll try my hand at a little bit of soldering...

All feedback / comments / tips for improvement most welcome!

Cheers,

BC