Hi all,

The cooling of the engine cylinders was carried out by cooled water from the radiator being fed by pipes to the water pump, located on the bottom, rear of the sump.

This water was pumped through an outlet pipe and through interconnected stub pipes at the bottom of each cylinder.

The water was then pumped up through the cylinders jackets and out through the interconnected stub pipes at the top of each cylinder, then forward to the front of the engine and back to the radiator for cooling.

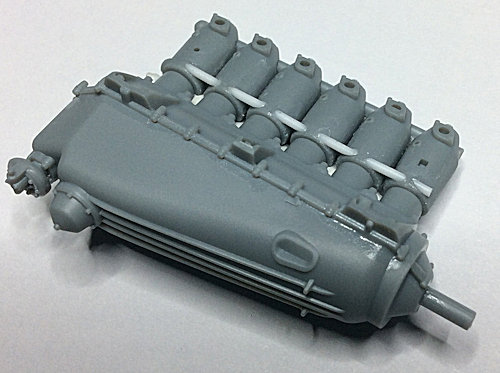

The kit supplied cylinder block has the pre-molded coolant pipe for the cylinder jackets, but it looks unrealistic, as it extends through and between the separate cylinders, presumably to act as a solid fixing base for the cylinder block.

I've cut this pre-molded pipe away to separate the cylinders and replaced it with short lengths of 0.85 mm diameter plastic rod, with a chamfer at at end to fit the contour of the cylinders.

Mike